Technician Productivity: Boost Wrench Time with Planning & Kitting

Technician Productivity: Strategies That Work

Technician productivity isn’t a motivation problem, it’s a management system problem. When planning, kitting, and schedule discipline click, wrench time climbs, costs fall, and teams feel proud of the work they complete.

Book a work Management Tune-Up

The Human Truth: Busy ≠ Productive

Some days I didn’t feel like working, and those days dragged. I looked busy because looking busy kept the questions away. The real problem? I wasn’t fully utilized. There wasn’t enough planned maintenance to keep me engaged for a full shift. A good day was simple: a full slate of well‑planned jobs, steady execution, and the satisfaction of real progress.

Managers in the Spotlight: Why Planning Matters

Utilization is a management outcome. Strong planners and schedulers change the math. When 18% of a tech’s day is spent hunting parts and 24–26% is spent walking to and from jobs, nearly half the day creates no value. Planning and kitting reclaim that time.

Two Levers That Move Wrench Time

-

Plan the work: technicians stop planning on the fly; job plans bring consistency.

-

Kit the work: parts, tools, and permits staged in advance; less time lost to searching.

Together, these levers can lift wrench time by ~50%.

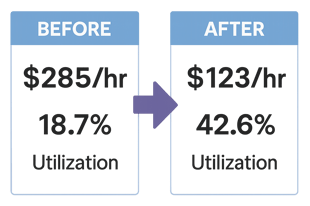

Case Study: From 18.7% → 42.6% Utilization

Before: 22‑person crew at 18.7% utilization—the equivalent of ~15 FTE idle while seven carried the load; effective labor $285/hour to complete work.

Actions: two techs moved into planner roles; implemented kitting; trained supervisors to remove obstacles and manage in the field.

After (quickly): 42.6% utilization; effective labor $123/hour; inventories −19.8% thanks to better planning and normal lead times.

When Roles Blur, Productivity Tanks

The assessment revealed a brittle setup: high turnover and no formal engineering team, with supervisors moonlighting as planners and pushing next-day schedules—so no real planning occurred.

-

Techs repairing on the fly; poor documentation.

-

81% of corrective work marked “48 hours”

-

13% of corrective work marked “24 hours”—no prioritization logic.

-

Utilization <12%; bloated inventory and expedite fees exceeding material costs.

The Fix: Five Guides + Clear Ownership

-

Asset management framework: FMECA/strategies/PMs to align risk and effort.

-

Work management process guide: identify → plan → schedule → execute → close → analyze.

-

Material management guide: demand planning, kitting, right part/right time.

-

Data management guide: hierarchy, BOMs, failure/cause codes, and data quality rules.

-

Roles & responsibilities: supervisors supervise; dedicated planners and schedulers; assign resources to PdM.

Putting Plans into Action (Org Design + Cadence)

-

New structure: 1 maintenance manager; 4 supervisors; 4 planners; 2 schedulers.

-

Weekly scheduling meeting with schedule freeze; storeroom kits PMs & planned work.

-

Writing process guides; CMMS cleanup (status/failure codes, backlog).

-

Outcomes: visible culture shift, lower turnover, and restored confidence in maintenance.

30/60/90‑Day Playbook

30 days

Stand up planning: top 20 job plans (scope, tools, parts, safety, estimates).

Publish priority + SLA matrix; stop marking everything urgent.

Lock failure/cause code sets; require time/parts at closeout.

60 days

Formal plan–schedule cadence with readiness gates and freeze.

Launch kitting for PMs and planned corrective work.

Supervisors coach in the field; verify closeout quality.

90 days

Move 1–2 high‑caliber techs into planner roles.

Review inventory vs planned demand; cut expedites; normalize lead times.

Run 1st RCA cycle; update strategies, job plans, and BOMs; publish a change log.

Metrics That Matter (Leading → Lagging)

-

Leading: plan coverage, kit completeness, schedule adherence, closeout completeness (% time/parts/failure/cause).

-

Lagging: utilization/wrench time, rework rate, maintenance cost/asset, availability.

Common Pitfalls to Avoid

Supervisors doing planning “on the side”; no schedule freeze; constant break‑ins; overlong low‑value PMs; missing BOMs; weak failure/cause coding; treating the CMMS like a filing cabinet, not a system of work.

FAQ

What boosts wrench time fastest?

Planning + kitting + weekly schedule discipline with a freeze and readiness gates.

Where should planners come from?

High‑caliber techs with system thinking—move 1–2 into planning to seed the function.

How do we stop everything being “urgent”?

Publish a priority/SLA matrix tied to risk and value; audit exceptions weekly.

Which data fields matter most at closeout?

Time, parts, failure and cause codes; make them mandatory and audited.

Topics: facilitiesnet, Work Management, Article

Posted by

Nexus Global

Recognized globally, across various industries, for delivering sustainable solutions that optimize both the organization’s assets and processes to yield a ROI of 10:1 or greater. Nexus Global Business Solutions, Inc. has been a worldwide leader in asset performance management and maintenance consulting, coaching and training for 15+ years.